Table of Contents

Offline filters are crucial for maintaining the cleanliness and efficiency of hydraulic and lubrication systems. These filters operate independently of the main system, offering continuous filtration and increased system reliability. In this article, we’ll explore how offline filters work, their benefits, and how to choose the right solution for your industrial needs.

How Offline Filters Work

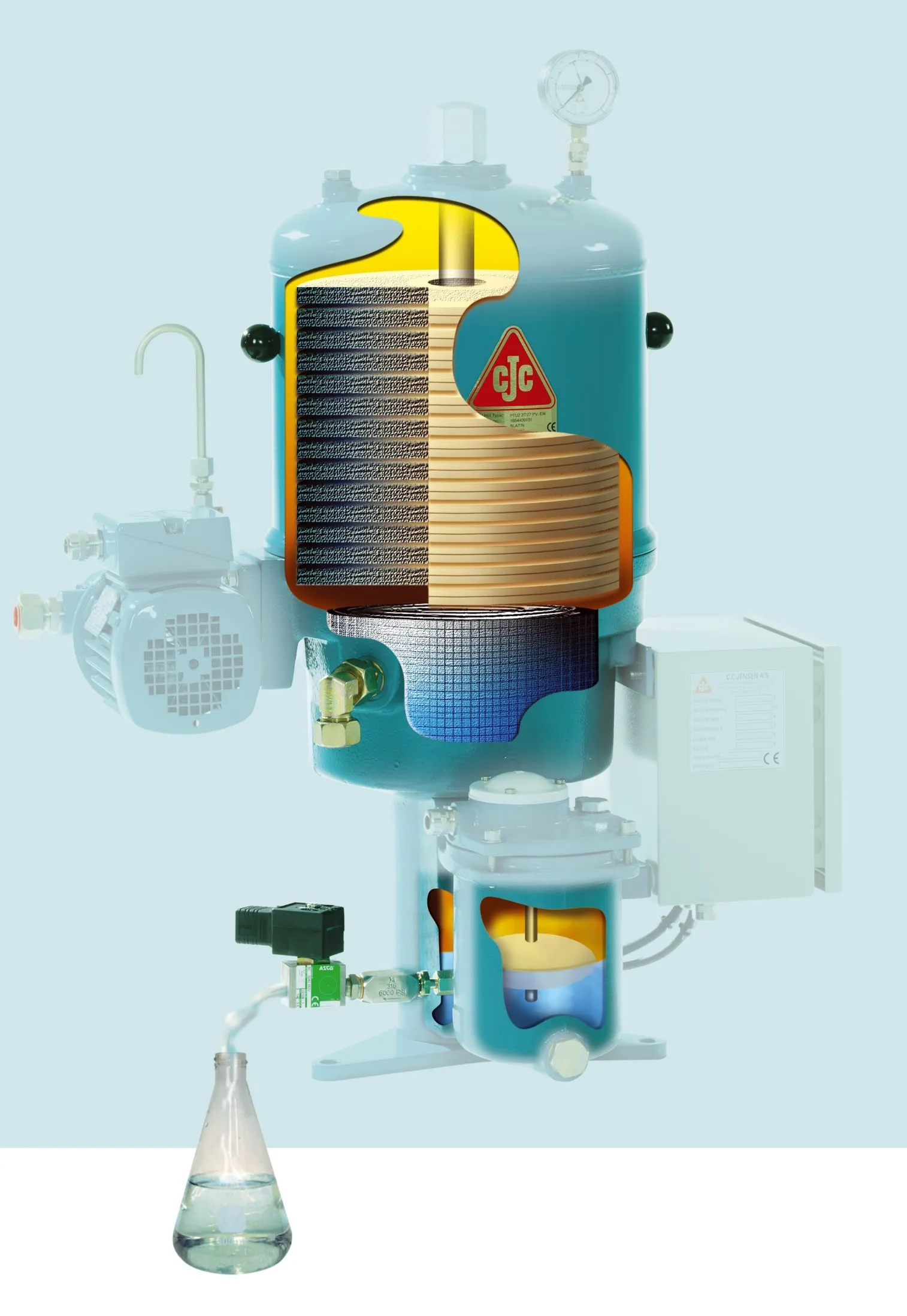

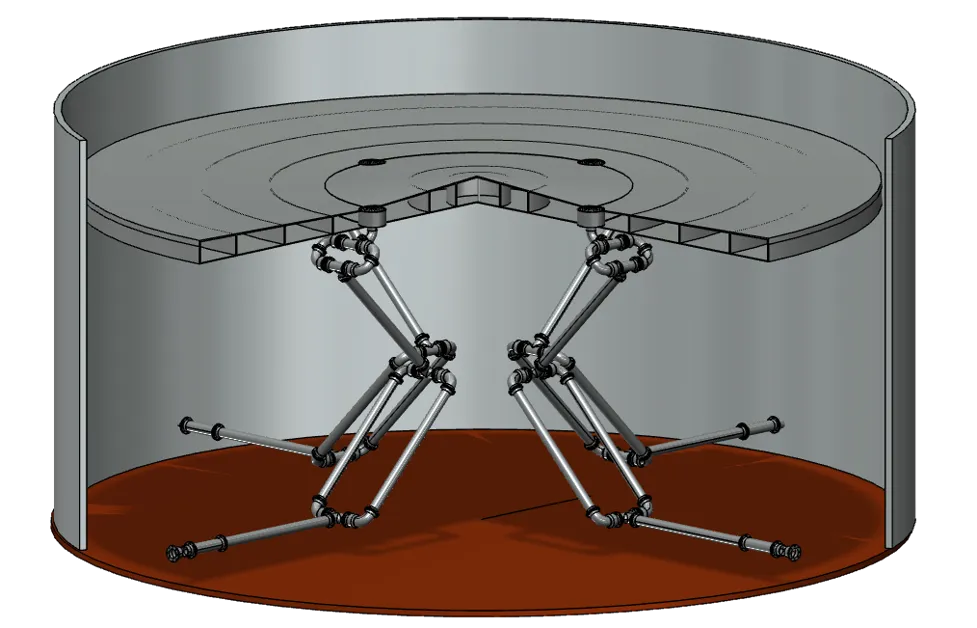

Offline filters, also known as kidney loop filters, operate independently from the main hydraulic or lubrication circuit. Unlike inline filters that handle high flow and pressure, offline units use a separate pump and motor to draw fluid, filter it, and return it back to the reservoir. This continuous loop ensures that oil cleanliness is maintained even when the main system is idle.

These systems are particularly useful for critical machinery where downtime is costly. Their placement allows them to filter contaminants without disrupting operational flow or causing pressure drops.

Benefits of Using Offline Filters

Using offline filters offers numerous benefits that enhance both short-term and long-term system performance:

- Improved Fluid Cleanliness: Offline filters continuously remove water, particulates, and sludge, maintaining optimal oil quality.

- Extended Equipment Life: Cleaner oil reduces component wear, lowering the risk of failure and extending machinery lifespan.

- Reduced Maintenance Costs: Systems with offline filtration require less frequent oil changes and have lower unplanned maintenance rates.

- Enhanced Performance: Stable and clean fluid improves efficiency, response time, and precision in hydraulic equipment.

According to industry data, maintaining ISO cleanliness levels with offline filters can extend component life by up to 3-5 times.

- Improved Fluid Cleanliness: Offline filters continuously remove water, particulates, and sludge, maintaining optimal oil quality.

Choosing the Right Offline Filter

Selecting the right offline filter involves several key considerations:

- Flow Rate Requirements: Ensure the filter can handle the fluid volume in your system.

- Contamination Type: Choose filter media suited for the contaminants present (e.g., water removal vs. particulate).

- System Compatibility: Look for solutions that integrate easily with your existing equipment, whether mobile or stationary.

- Operating Conditions: High-pressure, temperature, or aggressive chemical environments require durable filter housings and seals.

EPS offers a wide range of customizable offline filters designed for hydraulic, lubrication, and gear oil systems, with expert support to help match the right solution to your application.

Offline filters play a critical role in protecting hydraulic and lubrication systems across a range of industries from manufacturing to marine and energy. By continuously removing contaminants and stabilizing fluid cleanliness, they significantly enhance equipment reliability and reduce downtime. Whether you need offline filtration for a small gear pump or a large industrial hydraulic circuit, EPS Malaysia provides reliable offline filters tailored to your operational needs.