Table of Contents

In modern industrial environments, varnish buildup in lubricating oils and hydraulic systems can drastically reduce equipment performance and lead to costly failures. Varnish removal systems offer a reliable solution to prevent equipment downtime and extend oil life. In this article, we explore how these systems work, why they’re critical for heavy machinery, and how they contribute to operational efficiency.

Understanding Varnish and Its Impact

Varnish is a byproduct of oil oxidation, degradation, and contamination in hydraulic and lubrication systems. Over time, it deposits as a thin, sticky residue on internal components, causing valve sticking, increased friction, filter clogging, and overheating. According to industry studies, varnish is one of the leading causes of unplanned maintenance in turbines, compressors, and hydraulic systems. Detecting varnish early and implementing effective removal methods is key to maintaining system health.

How Varnish Removal Systems Work

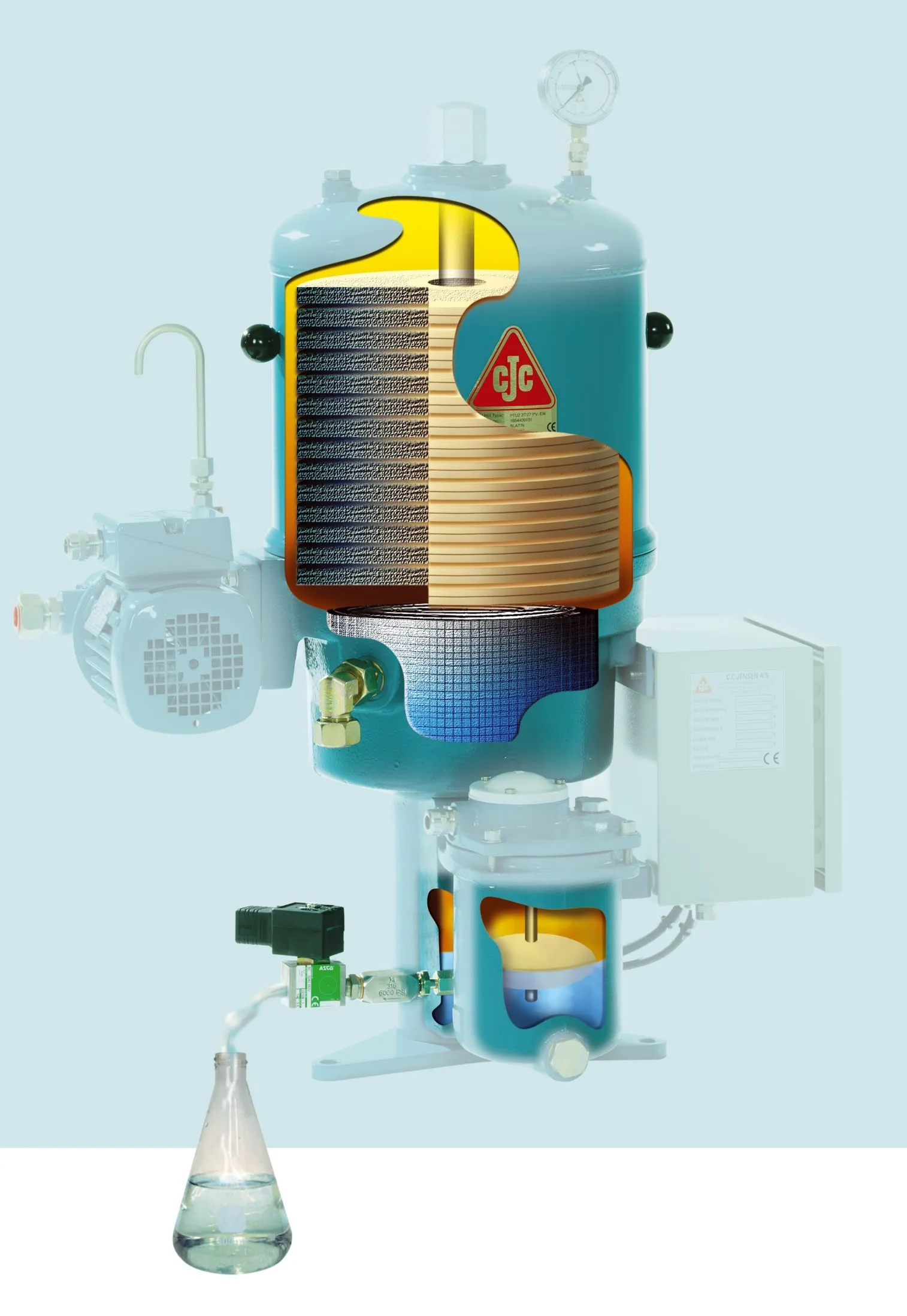

Modern varnish removal systems employ advanced technologies like electrostatic cleaning, depth filtration, and ion-exchange resins to capture and remove sub-micron particles and soft contaminants. These systems are typically offline units that work independently of the main equipment, ensuring minimal disruption. One notable technique is depth filtration, which the filter insert used naturally attracts polar contaminants like varnish, offering high efficiency without affecting oil additives. By continuously removing varnish precursors, these systems maintain optimal oil cleanliness levels

Benefits of Using Varnish Removal Systems

Implementing a varnish removal system brings numerous benefits:

- Extended Equipment Life: By preventing internal varnish buildup, machinery runs smoother and lasts longer.

- Reduced Maintenance Costs: Less varnish means fewer unplanned shutdowns and less frequent oil changes.

- Improved System Efficiency: Clean oil leads to better heat transfer, consistent flow, and stable performance.

Choosing the Right Varnish Removal Solution

When selecting a varnish removal system, it’s essential to consider factors such as:

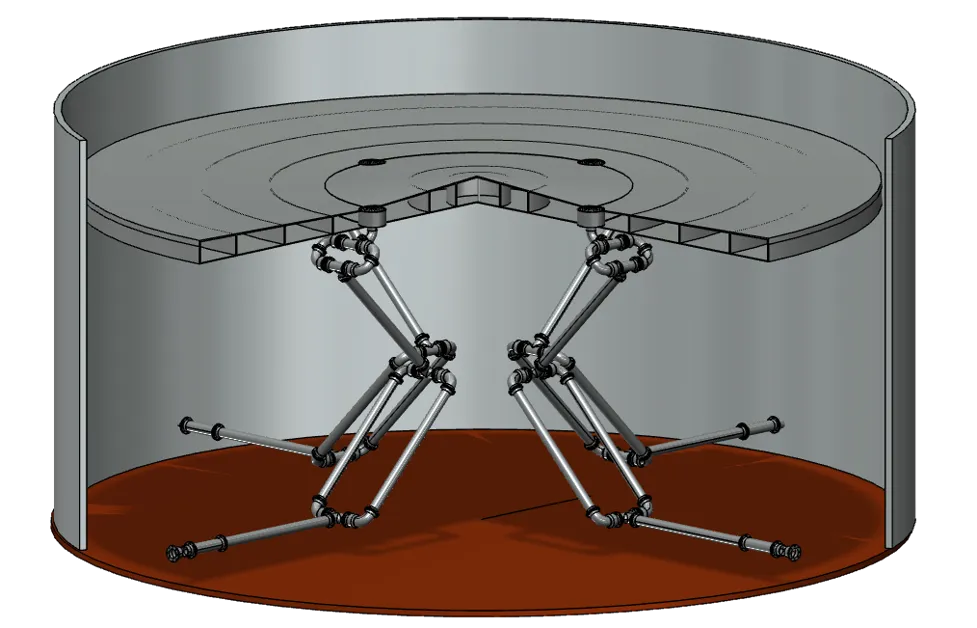

- System Size and Compatibility: Choose systems that match your reservoir size and oil type.

- Contaminant Load: High varnish levels may require more aggressive technologies.

- Oil Compatibility and Additives: Ensure the removal system doesn’t strip essential additives.

- Vendor Support and Customization: Look for experienced providers like EPS who offer tailored solutions, technical support, and proven success in industrial applications.

Varnish removal systems are vital in ensuring uninterrupted operations and maximizing the life span of your lubrication and hydraulic systems. With rising demands for efficiency and reliability, investing in the right varnish mitigation technology is not optional but it’s essential. At EPS, we provide advanced, customizable varnish removal systems tailored to your specific needs.