Table of Contents

Oil filtration systems play a vital role in maintaining the performance and longevity of industrial machinery. In Malaysia’s growing industrial sector, investing in an advanced oil filtration system is essential to ensure optimal equipment function, reduce wear and tear, and lower operational costs. This article explores the types, benefits, and technology behind oil filtration systems to help you make informed decisions.

Importance of Oil Filtration in Industrial Settings

Industrial equipment is often subjected to extreme conditions, making it susceptible to contamination from particles, water, and sludge. Without an efficient oil filtration system, lubricants degrade faster, leading to increased friction, overheating, and premature failure. Clean oil is essential for preventing downtime and ensuring the smooth operation of critical components such as engines, hydraulics, turbines, and compressors.

According to industry data, over 70% of mechanical failures are caused by oil contamination and highlighting the importance of proactive filtration.

Types of Oil Filtration Systems Available in Malaysia

Malaysia’s industrial sector utilizes a variety of oil filtration systems tailored to specific applications. The most common systems include:

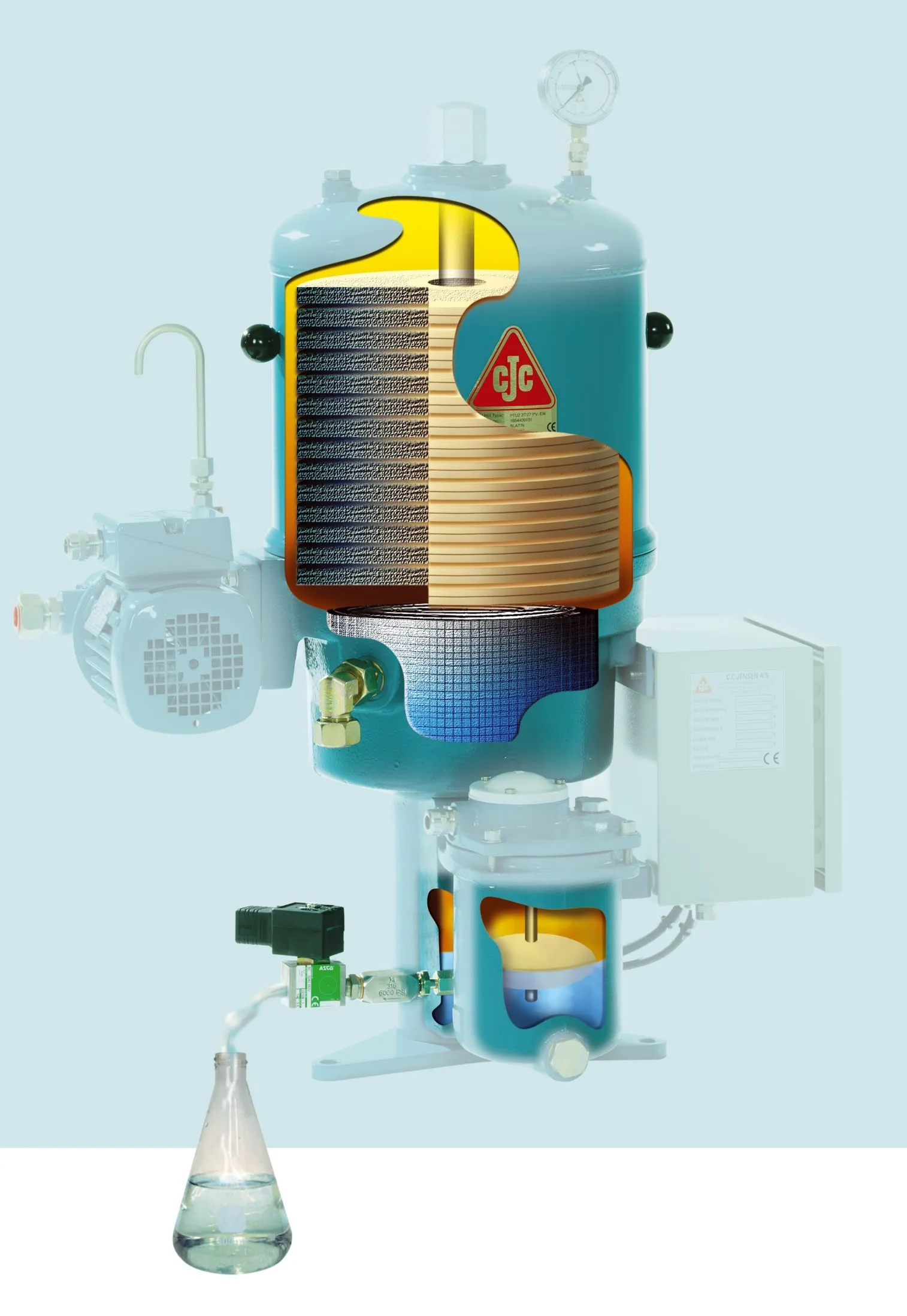

- Offline Filtration Systems: These operate separately from the main lubrication circuit, filtering oil continuously without disrupting operations. It uses special filter insert that can remove particles, water and varnish simultaneously.

- Vacuum Dehydration Units: Used to remove water, gases, and particulates from lubricants and hydraulic fluids.

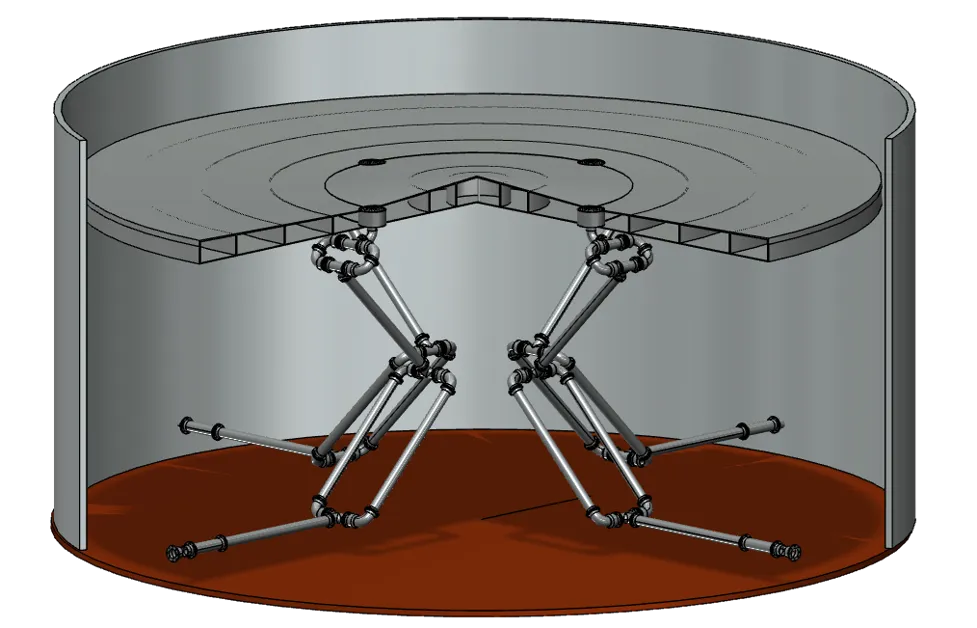

- Centrifugal Filtration: Separating water and solids from oil using centrifugal force, common in marine and power generation industries.

- High-Pressure Inline Filters: Commonly supplied by OEM and are essential in most machines for protection purposes.

EPS Malaysia provides customized solutions based on application requirements, ensuring compatibility with local and international industrial standards.

Benefits of Using Advanced Oil Filtration Solutions

Upgrading to an advanced oil filtration system offers several benefits, including:

- Extended Equipment Life: Clean oil reduces component wear, minimizing downtime and repair costs.

- Improved System Efficiency: Optimized lubrication helps maintain performance, reducing energy consumption.

- Lower Maintenance Costs: Fewer oil changes and reduced contamination-related failures result in significant cost savings.

- Environmental Benefits: Proper filtration reduces oil waste and supports eco-friendly operations.

Companies that implement advanced filtration often report up to 40% reduction in maintenance costs over five years.

Investing in an advanced oil filtration system is not just a preventive measure, it’s a strategic decision to safeguard industrial assets, reduce costs, and enhance operational efficiency. Whether you’re upgrading an existing system or planning a new installation, EPS offers tailored solutions to meet your oil purification needs.