Table of Contents

Oil condition monitoring systems in Malaysia have become essential for companies seeking to reduce machinery downtime and extend equipment lifespan. By continuously assessing the health of lubricants, these systems enable predictive maintenance, minimize unexpected failures, and enhance operational efficiency. This article explores how oil monitoring technologies are transforming industrial maintenance strategies.

Understanding Oil Condition Monitoring Systems

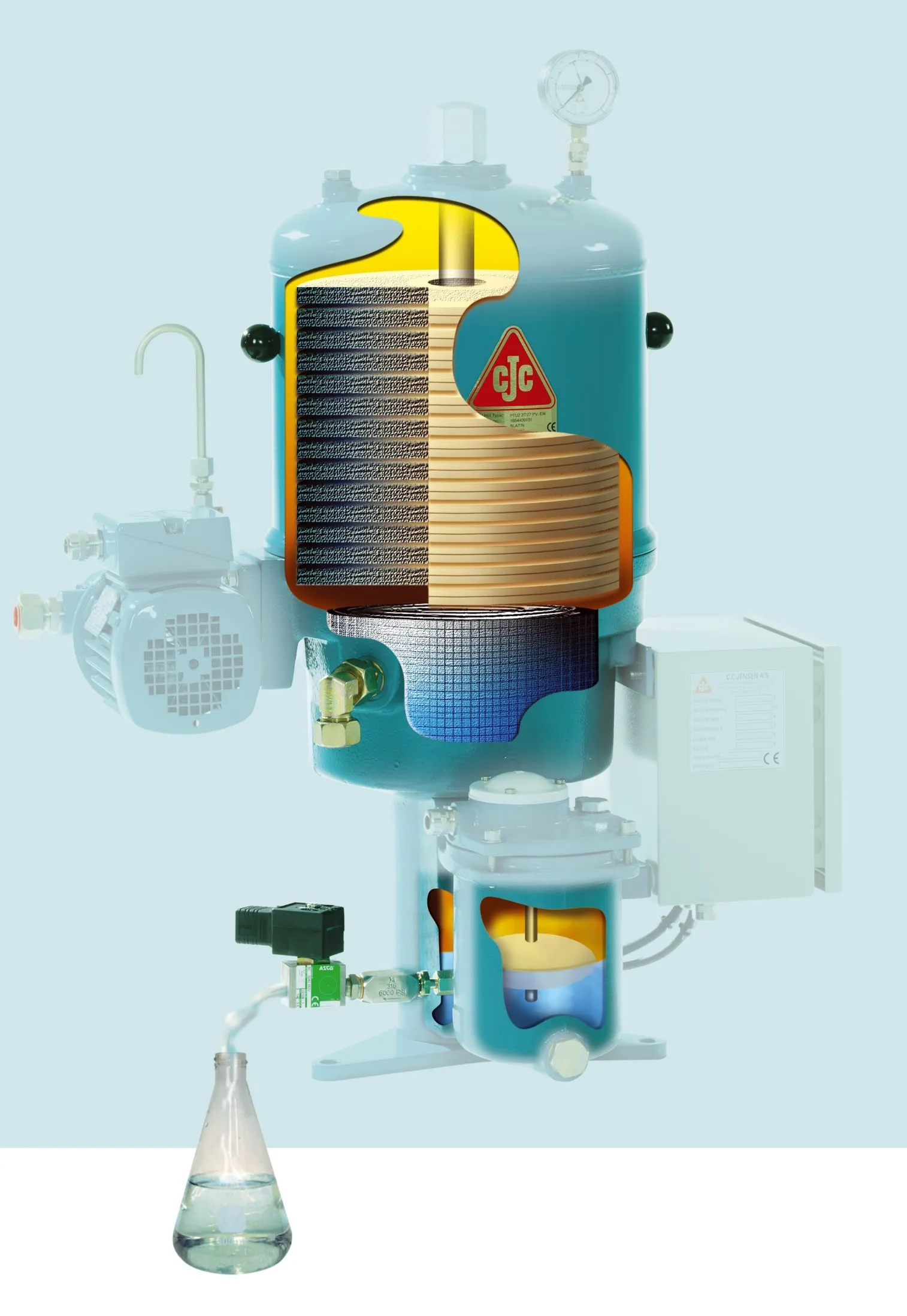

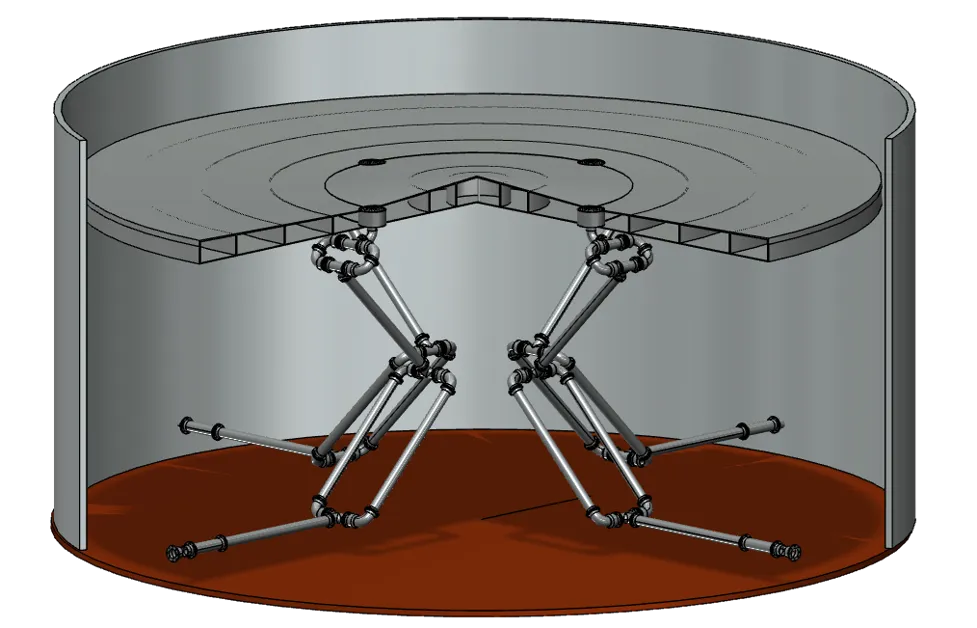

Oil condition monitoring systems are diagnostic tools designed to analyze the physical and chemical properties of lubricants in real-time. These systems detect wear particles, oxidation, water contamination, viscosity changes, and other vital indicators. When deployed correctly, they provide early warning signs of equipment deterioration, allowing maintenance teams to take action before failures occur. This proactive approach is especially critical in industries like power generation, marine, transportation, and manufacturing, where equipment reliability is non-negotiable.

Benefits of Predictive Maintenance Using Oil Analysis

Incorporating oil condition monitoring into your predictive maintenance strategy offers multiple benefits:

- Reduced Downtime: Early detection prevents unplanned stops, saving valuable production time.

- Extended Oil and Equipment Life: Real time oil monitoring helps maintain optimal lubrication, and know exactly when to change the oil.

- Cost Efficiency: Avoiding catastrophic failures lowers maintenance and replacement costs.

- Data-Driven Decisions: Continuous monitoring provides actionable insights, allowing more accurate service intervals and resource planning.

According to industry studies, predictive maintenance can reduce breakdowns by up to 70% and cut maintenance costs by 25–30%.

EPS’s Expertise in Oil Monitoring Solutions

EPS stands at the forefront of delivering reliable oil condition monitoring systems tailored to industrial needs. Their systems are designed with advanced sensors and real-time analytics, enabling clients to make smarter maintenance decisions. EPS solutions are trusted across sectors including power plants, heavy equipment, marine, and process industries.

With a strong commitment to quality, EPS not only provides the hardware but also end-to-end services, system integration, calibration, and technical support to ensure optimal performance. Their offerings comply with international standards and are customizable to meet specific operational challenges.

Oil condition monitoring systems are revolutionizing how industries in Malaysia approach equipment maintenance. By enabling predictive maintenance and improving machinery performance, these systems save costs, enhance safety, and extend asset life. EPS is a proven partner in this space, offering cutting-edge technology and expert service.