Table of Contents

What Are Tan Delta Oil Monitoring Sensors?

Tan Delta oil monitoring sensors are advanced diagnostic tools that continuously analyze the condition of lubricating oil in machinery and vehicles. Unlike traditional methods, these sensors provide real-time data on oil degradation, contamination, and performance.

They are known for their high sensitivity and reliability, making them essential for predictive maintenance strategies in Malaysian industries.

Benefits of Using Tan Delta Oil Monitoring Sensors in Malaysia

1. Reduced Maintenance Costs

By using Tan Delta sensors, companies can switch from scheduled to condition-based maintenance, reducing unnecessary oil changes and part replacements.

2. Extended Equipment Life

Monitoring oil in real time helps prevent wear and tear caused by using contaminated or degraded oil, prolonging machinery life.

3. Environmental Sustainability

Fewer oil changes mean less waste oil, supporting Malaysia’s sustainability goals.

4. Improved Operational Efficiency

With instant alerts on oil conditions, technicians can respond quickly, minimizing catastrophic failure and downtime.

Industries That Benefit from Oil Monitoring Technology

Tan Delta oil monitoring sensors Malaysia are widely adopted in:

- Maritime & Shipping: Monitoring engines and hydraulics.

- Construction: Heavy machinery and excavators.

- Manufacturing: Industrial equipment and automation systems.

- Energy Sector: Power plants and renewable energy sites.

- Transportation & Logistics: Fleet management.

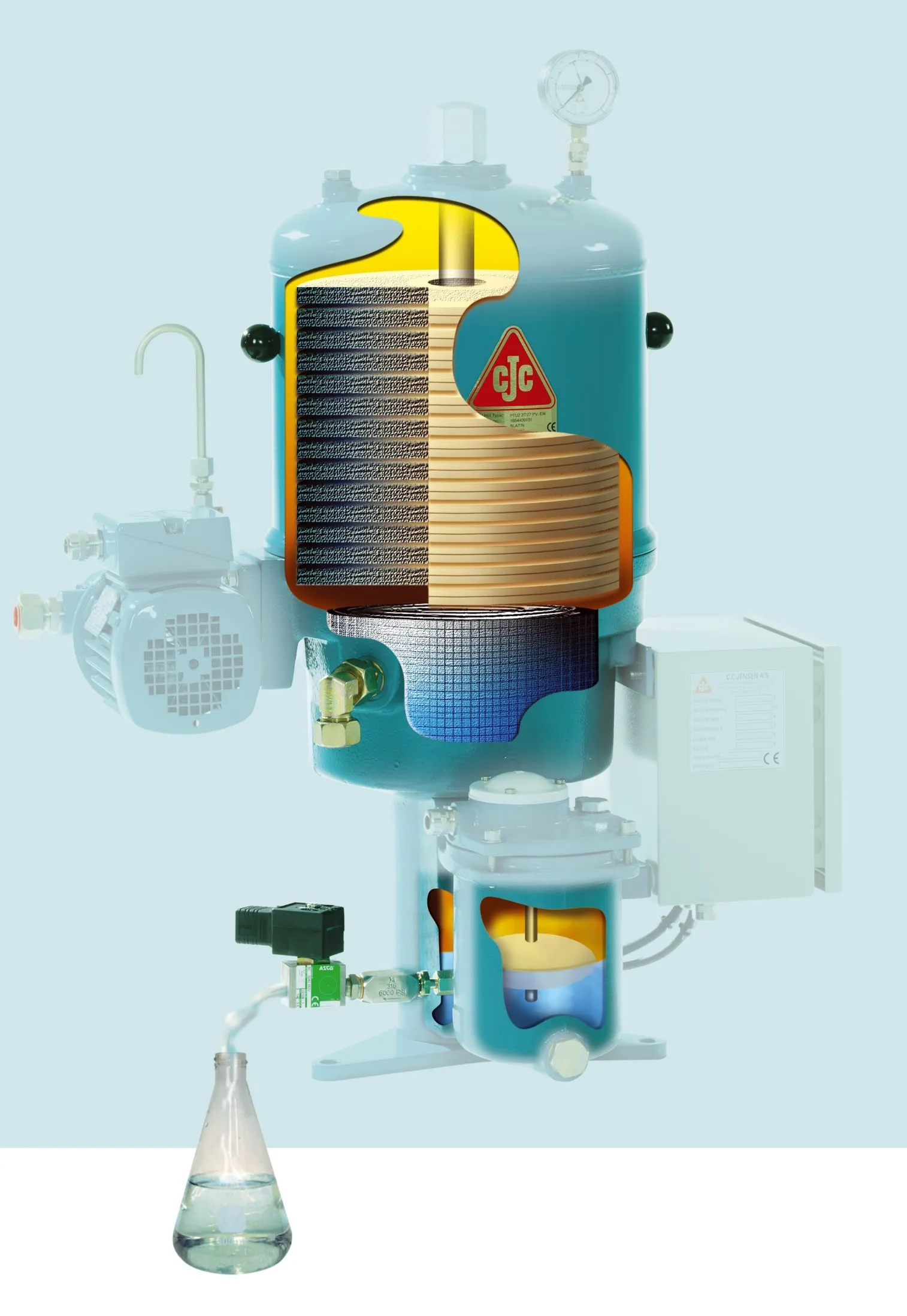

How Tan Delta Sensors Work

Tan Delta sensors use electrochemical analysis to continuously monitor the dielectric properties of the oil. This data is converted into a Tan Delta Oil Quality Index (OQI), providing a clear view of oil health.

The sensors can be integrated into existing systems, and data can be viewed via cloud platforms or onboard displays, enabling instant decision-making.

Investing in Tan Delta oil monitoring sensors Malaysia is a smart move for businesses aiming to reduce costs, enhance reliability, and embrace data-driven maintenance. With real-time oil condition data at your fingertips, you can make informed decisions that protect your assets and improve your bottom line.